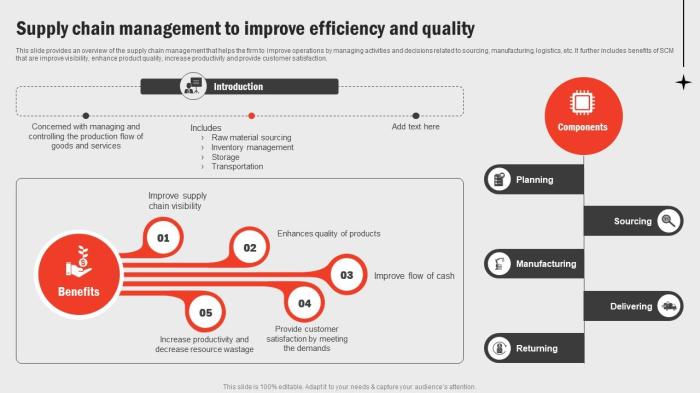

Optimizing your supply chain is crucial for any business aiming for sustainable growth and profitability. A well-structured, efficient supply chain translates directly to reduced costs, faster delivery times, and increased customer satisfaction. This guide explores practical strategies for identifying bottlenecks, implementing innovative technologies, and measuring the impact of improvements, ultimately leading to a more responsive and resilient operation.

From assessing your current processes to integrating cutting-edge technologies like AI and blockchain, we’ll delve into the key elements necessary for transforming your supply chain into a high-performing engine for your business. We will cover practical steps, actionable advice, and real-world examples to help you navigate this crucial aspect of business management.

Assessing Your Current Supply Chain

Understanding your current supply chain’s strengths and weaknesses is the crucial first step towards improvement. A thorough assessment allows for the identification of bottlenecks, inefficiencies, and areas ripe for optimization, ultimately leading to a more streamlined and profitable operation. This involves analyzing various aspects of your supply chain, from procurement to delivery, and identifying where improvements can be made.

Key Areas of Supply Chain Inefficiency

Three common areas of inefficiency plague many supply chains. These include inventory management, transportation logistics, and information flow. Inefficient inventory management leads to excessive storage costs, potential spoilage, and lost sales opportunities due to stockouts. Poor transportation logistics can result in delayed shipments, increased transportation costs, and damage to goods. Finally, inadequate information flow can lead to inaccurate forecasting, poor coordination among supply chain partners, and ultimately, dissatisfied customers.For example, a retailer holding excessive inventory of seasonal products experiences high warehousing costs and potential losses from unsold items.

A manufacturer relying on inefficient trucking routes faces higher transportation costs and potential delays in delivering goods to customers. A company with a poorly integrated information system struggles to accurately forecast demand, leading to either overstocking or stockouts.

Reactive versus Proactive Supply Chain Performance

Reactive and proactive supply chains differ significantly in their performance metrics and overall effectiveness. A reactive supply chain responds to events as they occur, often leading to firefighting and inefficient resource allocation. A proactive supply chain, in contrast, anticipates potential disruptions and proactively implements strategies to mitigate their impact.

| Metric | Reactive Supply Chain | Proactive Supply Chain |

|---|---|---|

| Inventory Turnover | Low, leading to high holding costs and potential obsolescence. | High, minimizing storage costs and maximizing sales opportunities. |

| On-Time Delivery | Variable and often below target, leading to customer dissatisfaction. | High and consistent, ensuring customer satisfaction and loyalty. |

| Order Fulfillment Time | Long and unpredictable, resulting in delayed deliveries and lost sales. | Short and predictable, enabling efficient order processing and quick delivery. |

| Cost of Goods Sold | High due to inefficiencies in inventory management and transportation. | Lower due to optimized processes and proactive risk management. |

| Customer Satisfaction | Often low due to delays and unreliable service. | High due to reliable and timely deliveries. |

Reactive supply chains, while simpler to implement initially, often incur higher costs in the long run due to unplanned expenditures and lost opportunities. Proactive supply chains require more upfront investment in technology and planning but offer significant long-term benefits in terms of cost savings, improved efficiency, and enhanced customer satisfaction. For example, a company that only responds to supply shortages after they occur will face higher costs and potential lost sales compared to a company that proactively monitors supply levels and anticipates potential disruptions.

Supply Chain Audit Process

A structured audit is essential for pinpointing bottlenecks and areas for improvement. This involves systematically reviewing each stage of the supply chain, identifying performance metrics, and evaluating potential solutions. The following table Artikels a sample audit process:

| Process | Current Performance | Bottleneck | Potential Solution |

|---|---|---|---|

| Procurement | Average lead time of 4 weeks; high rejection rate of 5%. | Supplier lead times and quality inconsistencies. | Negotiate shorter lead times with key suppliers; implement stricter quality control measures. |

| Production | Production capacity utilization at 80%; frequent machine breakdowns. | Insufficient production capacity; inadequate maintenance program. | Invest in additional production capacity; implement a preventative maintenance schedule. |

| Warehousing | High inventory holding costs; slow order fulfillment. | Inefficient warehouse layout; outdated inventory management system. | Optimize warehouse layout; implement a new inventory management system with real-time tracking. |

| Transportation | High transportation costs; inconsistent delivery times. | Inefficient routing; reliance on a single carrier. | Optimize transportation routes using route planning software; diversify carriers. |

| Customer Service | High number of customer complaints; long response times. | Inadequate customer service resources; lack of real-time order tracking. | Increase customer service staffing; implement a real-time order tracking system. |

Strategies for Improvement

Optimizing your supply chain requires a strategic approach focusing on efficiency and responsiveness. This involves examining existing processes, identifying bottlenecks, and implementing innovative solutions to streamline operations and reduce costs. By strategically leveraging technology and refining inventory management, significant improvements can be achieved.

Just-in-Time Inventory Management

Just-in-Time (JIT) inventory management aims to minimize inventory holding costs by receiving materials only when needed for production. This reduces storage space requirements, minimizes waste from obsolescence or spoilage, and frees up capital that would otherwise be tied up in inventory. The core principle is to synchronize production with demand, ensuring a constant flow of materials without excessive stockpiling.For example, a car manufacturer using JIT might receive engine components directly from the supplier just before they are needed on the assembly line.

This eliminates the need for large warehouses to store engines, reducing storage costs and the risk of damage or obsolescence. Similarly, a fast-food restaurant employing JIT principles might receive fresh produce daily, ensuring product freshness while minimizing waste from spoilage. The success of JIT depends on reliable suppliers and precise demand forecasting.

Technological Advancements in Supply Chain Optimization

Technology plays a crucial role in modern supply chain optimization. Two significant technologies are Artificial Intelligence (AI) and Blockchain.AI offers predictive capabilities, enabling more accurate demand forecasting and proactive inventory management. For instance, AI algorithms can analyze historical sales data, weather patterns, and economic indicators to predict future demand, allowing businesses to adjust production and procurement accordingly. This reduces stockouts and overstocking, leading to significant cost savings.

Furthermore, AI-powered systems can optimize logistics routes, reducing transportation costs and delivery times.Blockchain technology enhances transparency and traceability throughout the supply chain. By recording all transactions on a secure, distributed ledger, blockchain provides a verifiable record of product origin, movement, and handling. This is particularly beneficial in industries with stringent quality and safety requirements, such as pharmaceuticals or food.

For example, a food company could use blockchain to track the journey of its products from farm to table, ensuring consumers have complete transparency about the source and handling of their food. This enhances consumer trust and enables faster response to potential contamination or quality issues.

Integrating a New Technology: A Step-by-Step Plan

Integrating a new technology, such as AI-powered demand forecasting, requires a well-defined plan. The process can be challenging, but careful planning and execution can mitigate potential issues.

- Needs Assessment: Thoroughly assess your current supply chain’s needs and identify specific areas where the new technology can provide the most significant benefits. This involves analyzing existing data, identifying pain points, and defining clear objectives.

- Technology Selection: Research and select a suitable technology solution that aligns with your needs and budget. Consider factors such as scalability, integration capabilities, and vendor support.

- Data Integration: Integrate the new technology with your existing systems, ensuring seamless data flow between different platforms. This might involve data migration, API development, or system upgrades.

- Testing and Training: Thoroughly test the new system to identify and address any bugs or issues. Provide adequate training to your employees on how to use the new technology effectively.

- Implementation and Monitoring: Implement the new technology gradually, starting with a pilot program if possible. Continuously monitor the system’s performance and make adjustments as needed. This includes tracking key performance indicators (KPIs) to measure the impact of the technology on efficiency and cost.

Potential challenges include resistance to change from employees, data integration complexities, and unexpected costs. Solutions include providing comprehensive training and support to employees, engaging with experienced technology integrators, and establishing a detailed budget that accounts for potential unforeseen expenses.

Implementing and Measuring Change

Implementing supply chain improvements requires a structured approach, moving gradually through phases to minimize disruption and maximize the impact of changes. Effective monitoring and measurement are crucial to ensure that the implemented strategies deliver the expected results. Open communication and collaboration are vital for successful implementation across various departments.Successful implementation of supply chain improvements hinges on a well-defined plan, regular monitoring, and effective communication.

A phased approach allows for controlled rollout, enabling adjustments based on early feedback. Robust measurement systems ensure that the impact of changes can be accurately assessed, guiding future optimization efforts. Finally, fostering collaboration between departments ensures alignment and smooth execution of the improvement plan.

Phased Implementation of Supply Chain Improvements

A phased approach allows for manageable implementation and minimizes potential disruptions. Each phase builds upon the previous one, creating a foundation for continuous improvement. Key milestones and timelines should be established, along with clear performance indicators to track progress.

| Phase | Activities | Timeline | Key Performance Indicators (KPIs) |

|---|---|---|---|

| Assessment & Planning | Analyze current state, identify improvement areas, develop detailed plan, secure buy-in from stakeholders. | 1-2 months | Number of identified improvement areas, stakeholder buy-in rate, plan completion date. |

| Pilot Implementation | Implement changes on a smaller scale, gather data, refine processes. | 2-3 months | Pilot program success rate, reduction in lead times, improvement in inventory accuracy. |

| Full-Scale Implementation | Roll out changes across the entire supply chain, provide training and support. | 3-6 months | On-time delivery rate, order fulfillment cycle time, reduction in inventory holding costs. |

| Monitoring & Optimization | Continuously monitor KPIs, identify areas for further improvement, adjust strategies as needed. | Ongoing | Customer satisfaction scores, supplier performance metrics, overall supply chain efficiency. |

Tracking and Measuring Effectiveness

Tracking and measuring the effectiveness of implemented changes are essential for demonstrating return on investment (ROI) and identifying areas for further improvement. This involves regularly monitoring key performance indicators (KPIs) and comparing them to pre-implementation baselines.Relevant KPIs include:

- On-time delivery rate: Percentage of orders delivered on or before the promised delivery date.

- Order fulfillment cycle time: Time taken from order placement to delivery.

- Inventory turnover rate: Number of times inventory is sold and replaced during a specific period.

- Inventory holding costs: Costs associated with storing inventory, including warehousing, insurance, and obsolescence.

- Supplier performance metrics: On-time delivery, quality of goods, and responsiveness of suppliers.

- Customer satisfaction scores: Measured through surveys or feedback mechanisms.

- Supply chain costs: Total costs associated with the entire supply chain, including procurement, manufacturing, logistics, and distribution.

Fostering Collaboration and Communication

Effective communication and collaboration across departments are critical for successful supply chain improvement. Regular meetings, shared dashboards, and collaborative platforms facilitate information sharing and problem-solving. This enhances efficiency by reducing delays, minimizing errors, and fostering a shared understanding of goals and objectives. For example, a weekly cross-functional meeting involving procurement, logistics, and manufacturing could identify bottlenecks and develop solutions collaboratively.

A shared online dashboard displaying key KPIs in real-time enables all stakeholders to monitor progress and identify potential issues proactively.

Last Recap

By systematically evaluating your existing supply chain, strategically implementing improvements, and consistently monitoring performance, you can unlock significant gains in efficiency and profitability. Embracing technological advancements and fostering strong interdepartmental collaboration are key to creating a truly agile and responsive supply chain that can adapt to changing market demands and maintain a competitive edge. Remember, a well-oiled supply chain is the backbone of a thriving business.